FLOWROX

FLOWROX

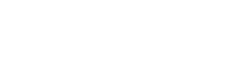

LPP-T delivery hose pump

Flow rate 2-100 m3/hr

Maximum pressure: 10 bar

Solid content: 80%

Head: 0-8m

LPP-D

- Mining industry, such as crushing, beneficiation, flotation, filtration, dosing and metering, etc.

- Wastewater treatment, such as scrap metal, activated sludge transport, dosing and metering, etc.

- Chemical industry, such as the transportation of acids, paints, resins, etc., and the measurement of related processes, etc.

- Oil and offshore industries

- Food Industry

- achitechive

- Pulp and paper industry, etc.

LPP-M

Flow rate 0-0.6 m3/hr

Maximum pressure: 8.6 bar

head: 0-2m

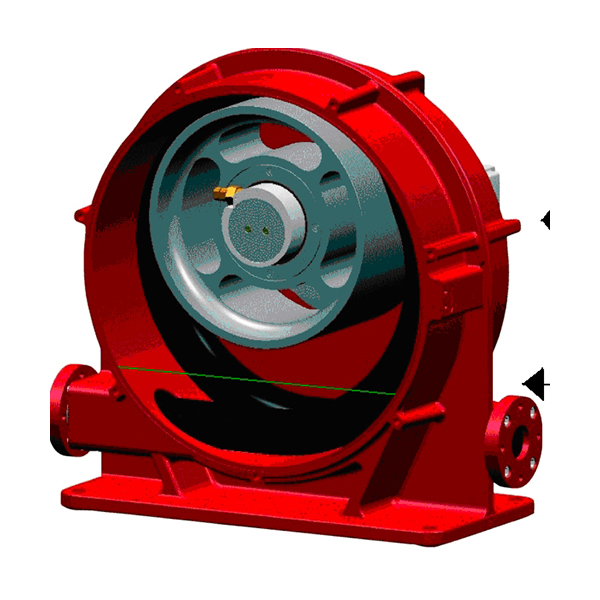

Flowrox pipe clamp valve features:

- High durability: The valve sleeve is the only component that comes into contact with the liquid. Maximum wear resistance and corrosion resistance can be achieved by selecting the appropriate elastomeric mass based on the liquid. Flowrox has been running for millions of times and its ability to open and close is consistent. The high-quality raw materials make the sleeves elastic and water-tight, and can be switched normally even in media that are easy to crystallize and scale.

- A variety of valve sleeve materials: Flowrox can provide you with the right materials, regardless of temperature up to 120 ° C, long-term wind and sun, or strong acid and alkali environment.

- Low flow resistance: In the fully open position, the valve sleeve becomes part of the overall straight pipe. The full diameter mode ensures unobstructed flow, which is important for coarse mud. The unique design of the Flowrox valve also guarantees low flow resistance. Superior fluidity considerably reduces the loss of energy in the pipeline, which means savings in pipeline transportation.

- Standardized structure: You can choose any combination of drive, valve body and valve sleeve according to your needs. The valve diameter range is 25mm-1000mm, the temperature range is -50°C- +100°C, the pressure range is 0 – 100 Bar, or you can Special requirements are customized.

- Widely used in: paper pulp industry, mining, cement industry, food processing industry, power plants, chemical plants, steel plants, wastewater treatment systems and pneumatic transmission systems.

Ceramic Disc

- High performance: Flowrox ceramic disc filter presses have a filtration capacity of up to 2000 kg DS/m2 per hour. The unit produces 240 tons per hour.

- Continuous job security: Automated and intelligent operating systems increase reliability and stability. The slurry is uniform and constant, making the process smoother.

- Energy saving: The total vacuum power is very low. It can reduce energy costs by up to 90% compared to conventional vacuum filters.

- Clearer filtrate and drier filter: The solids content of the filtrate is below 20 mg/l on average. Other types of filters typically have a solids content of a few hundred milligrams per liter or even a few grams per liter.

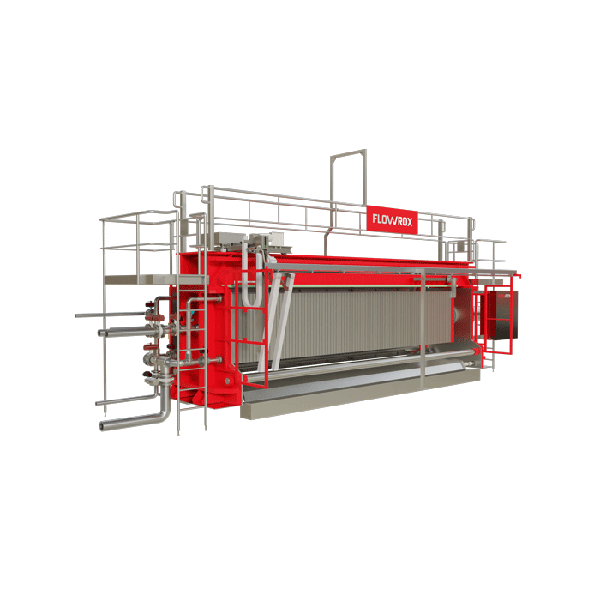

Filter Press

Optional features:

- Press cake

- Blow drying

- Washing cake

- Automatic filter cloth cleaning

- Filtrate quality monitoring

- Automatic filter cake cleaning